TERMOGASKET PU – Polyurethane is a new polymer material between plastic and rubber .

PU sheets and rood are made from branded raw materials Desmopan , German quality

PU is formed after chemical reaction of polymer polyalcohol and isocyanate through chain extension and cross linkage ,it is divided into polyether (PPG) and polyester according to its backbone chain.

PPG and Polyester sheet two kinds for clients to choose, Polyester is more excellent wear resistance than PPG,but PPG is more competitive in price.

Polyurethane can be adapted to comprise a wide range of unique properties, which is a key factor of its versatility.

Abrasion resistance,Toughness – Tensile strength, High load bearing ability, High tear resistance, Mechanical properties

Resistance to water, oil, grease, Electrical properties, Corrosion resistance

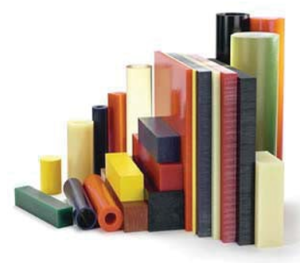

Assortment TERMOGASKET PU

| Product Name | Color | Thickness (mm) | Dimension (length*width) |

| PU Sheet | White/Yellow/Transparent,Red,Blue | 1mm~30mm | 1000mm*1200mm;1200*2000mm

1000mm*2000mm;1500*3000mm |

| PU Sheet | 30mm~200mm | 500mm*500m |

| Product Name | Diameter (mm) | Length (mm) | |||||||||

| PU Rod

Yellow/White/Brown,Red; |

¢10mm | ¢15mm | ¢20mm | ¢25mm | ¢30mm | ¢35mm | ¢40mm | ¢45mm | ¢50mm | ¢55mm | 500mm |

| ¢60mm | ¢65mm | ¢70mm | ¢75mm | ¢80mm | ¢85mm | ¢90mm | ¢95mm | ¢100mm | ¢110mm | ||

| ¢120mm | ¢130mm | ¢140mm | ¢150mm | ¢160mm | ¢180mm | ¢200mm | ¢250mm | ||||

Mechanical properties

| shore hardness А | 1s | – | DIN ISO 7619-1 | 85 | ||

| shore hardness D | 1s | – | DIN ISO 7619-1 | 32 | ||

| Ultimate tensile strength | 200 mm/min | МРa | Ь.o. ISO 527-1,-3 | 40 | ||

| Strain at Ьreak | 200 mm/min | % | Ь.o. ISO 527-1,-3 | 450 | ||

| Stress at 100 % strain | 200 mm/min | МРa | Ь.o. ISO 527-1,-3 | 6.0 | ||

| Stress at 300 % strain | 200 mm/min | МРa | Ь.o. ISO 527-1,-3 | 17 | ||

| Сompression set | 24 h; 70 °С | % | DIN ISO 815-1, Мethod А | 36 | ||

| Сompression set | 72 h; 23 °С | % | DIN ISO 815-1 | 30 | ||

| Сompression set | 24 h; 70 °С | % | DIN ISO 815-1, Мethod С | 25 | ||

| АЬrasion resistance | mm3 | ISO 4649 method А | 30 | |||

| ReЬound resilience | % | ISO 4662 | 42 | |||

| Tear strength | 500 mm/min | kN/m | ISO 34-1 | 70 |

Thermal properties

| Tensile storage modulus | -20 °С | МРa | ISO 6721-1,-4 | 186 | ||

| Tensile storage modulus | 20 °С | МРa | ISO 6721-1,-4 | 51 | ||

| Tensile storage modulus | 60 °С | МРa | ISO 6721-1,-4 | 37 |

Other properties (23 °С)

| Density | kg/m3 | ISO 1183-1 | 1200 |

Recommended processing and drying conditions

| Injection molding – Мelt temperature | °С | – | 210 – 230 | |||

| Injection molding – Мold temperature | °С | – | 20 – 40 | |||

| Мaximum drying temperature | °С | – | 80 |